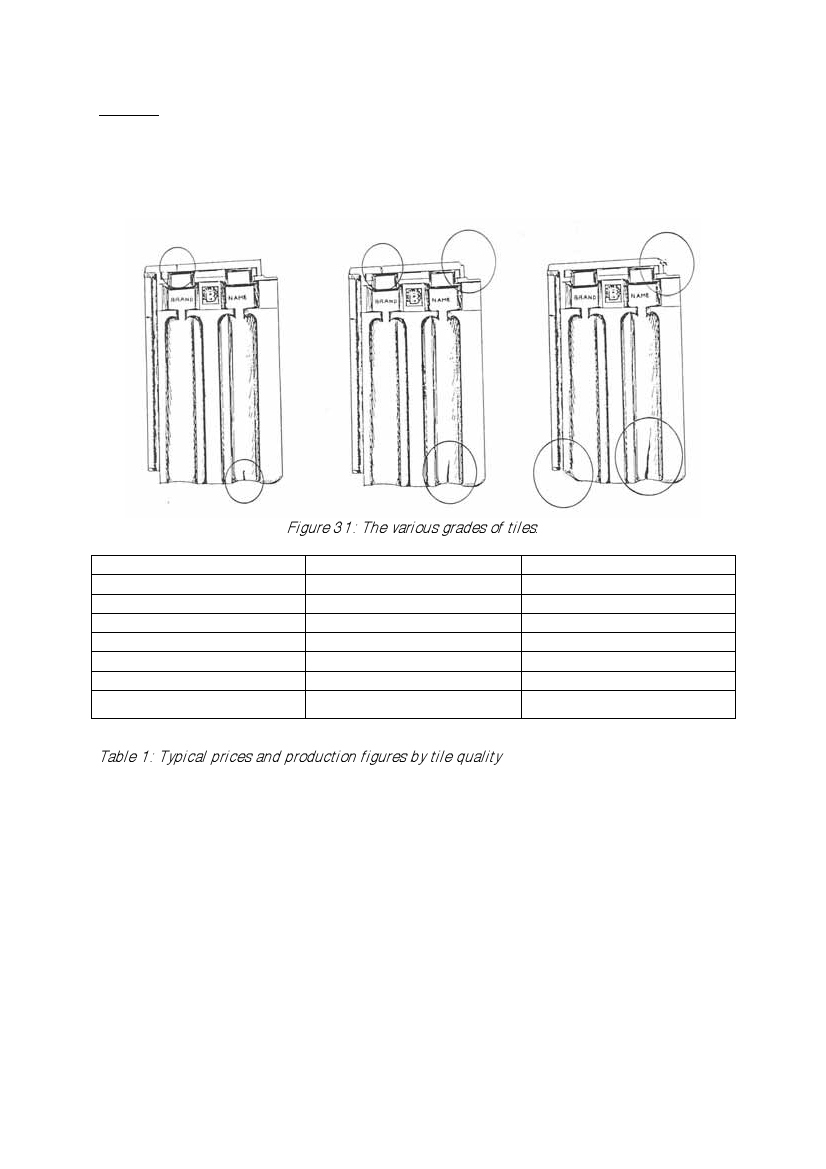

GRADING

When the kiln is unloaded each tile must be graded according to quality. In Sri Lanka, a

grade 1 tile has no visible cracks or significant chips, a grade 2 tile may have small flakes

missing, and cracks no longer than one inch, a grade 3 tile may have cracks under two

inches long, and grade 4 tiles may be further cracked with broken corners.

Grade

1

2

3

4

Loss

Aerage Total

Figure 31: The various grades of tiles.

Price (US $ per 1,000 tiles

125.00

100.00

61.00

28.00

% of Typical Load

87.5%

8.2%

3.3%

1.0%

$193/1,000

100%

Table 1: Typical prices and production figures by tile quality

5. BUDGET AND FINANCE

To give the reader some idea of the financial requirements of setting up a production unit, we

will review the actual cost as they are in early 1986 in Sri Lanka. It should be pointed out

that the importing tariffs are fairly low in Sri Lanka, so these figures may be considered as

pre-import values. Items marked with a star are locally produced. All Figures have been

converted into US$.

Building Structures ..............................................$3,750.00

Tractor and Trailer (new) ......................................$8,925.00

Kiln ....................................................................$ 4 ,690 .00

Drying Racks .......................................................$6,560.00

Drying Pallets (25,000) ........................................$7,140.00

Pugmill

Engine .................................................... $1 , 070 . 00

Pugmi 11 * .............................................. $1 , 785. 00